At Kelai Outdoormetal, a leading manufacturer of metal fencing and railing products, we focus on producing and supplying products with premium quality and we pride ourselves on our quality craftsmanship. Let’s see how we transform the raw materials into durable and appealing metal fencing, railing.

Plant aerial view

The production Process Introduction

1.Raw material

High-grade steel and aluminum alloys arrive at our factory and store in raw-material warehouse

2.Fabrication

Automatic cutting, punching, drilling with high precision, no dents or burrs left on material

For example, the precision for automatic cutting is at±0.01” (0.25mm), the precision for automatic punching and drilling is at ±0.02” (0.5mm)

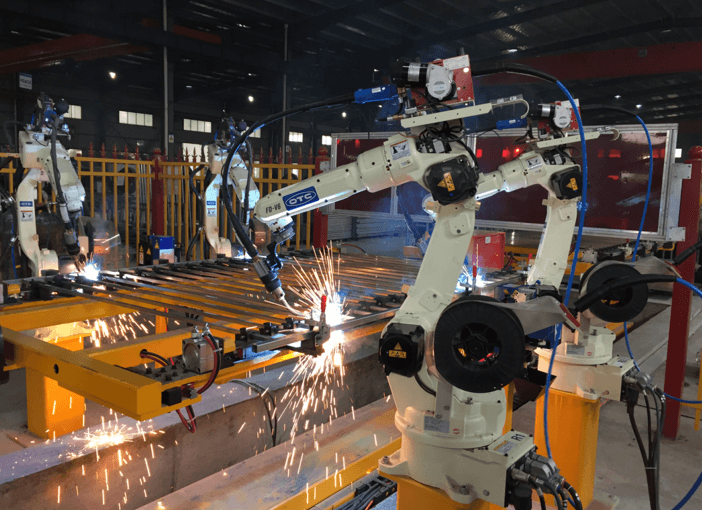

Robotic Welding machines for consistent quality and high efficiency

3.Surface Treatment

Automatic chemical concentration adjustment pre-treatment system to achieve superior adhesion between coating and base material

2 layer coating realize durable & perfect-touch powder coating and exceptional weather resistance with various colors available (AkzoNobel Powder)

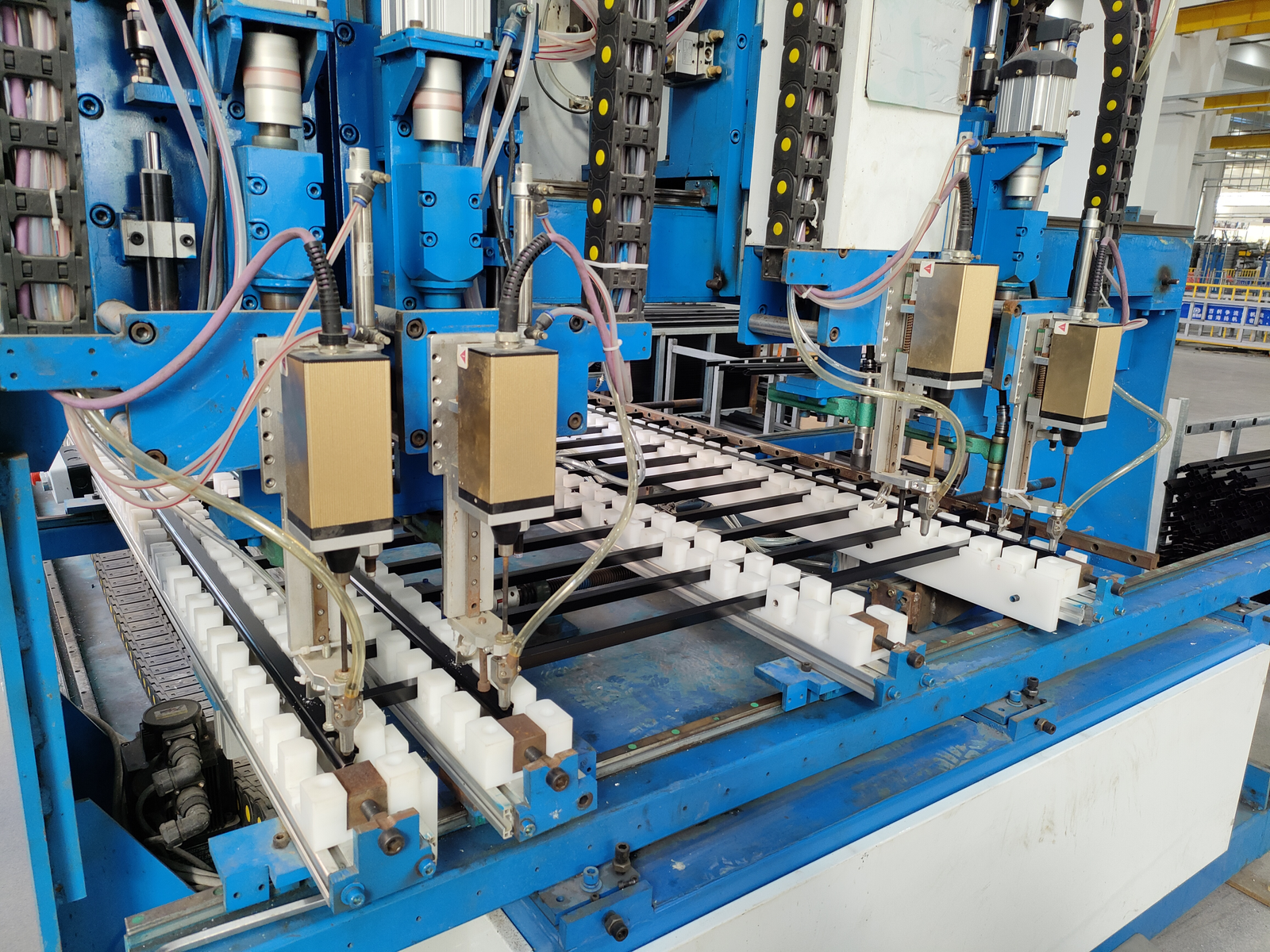

4.Assembly

Automatic assembly machines can finish 250 panels per 8 hours

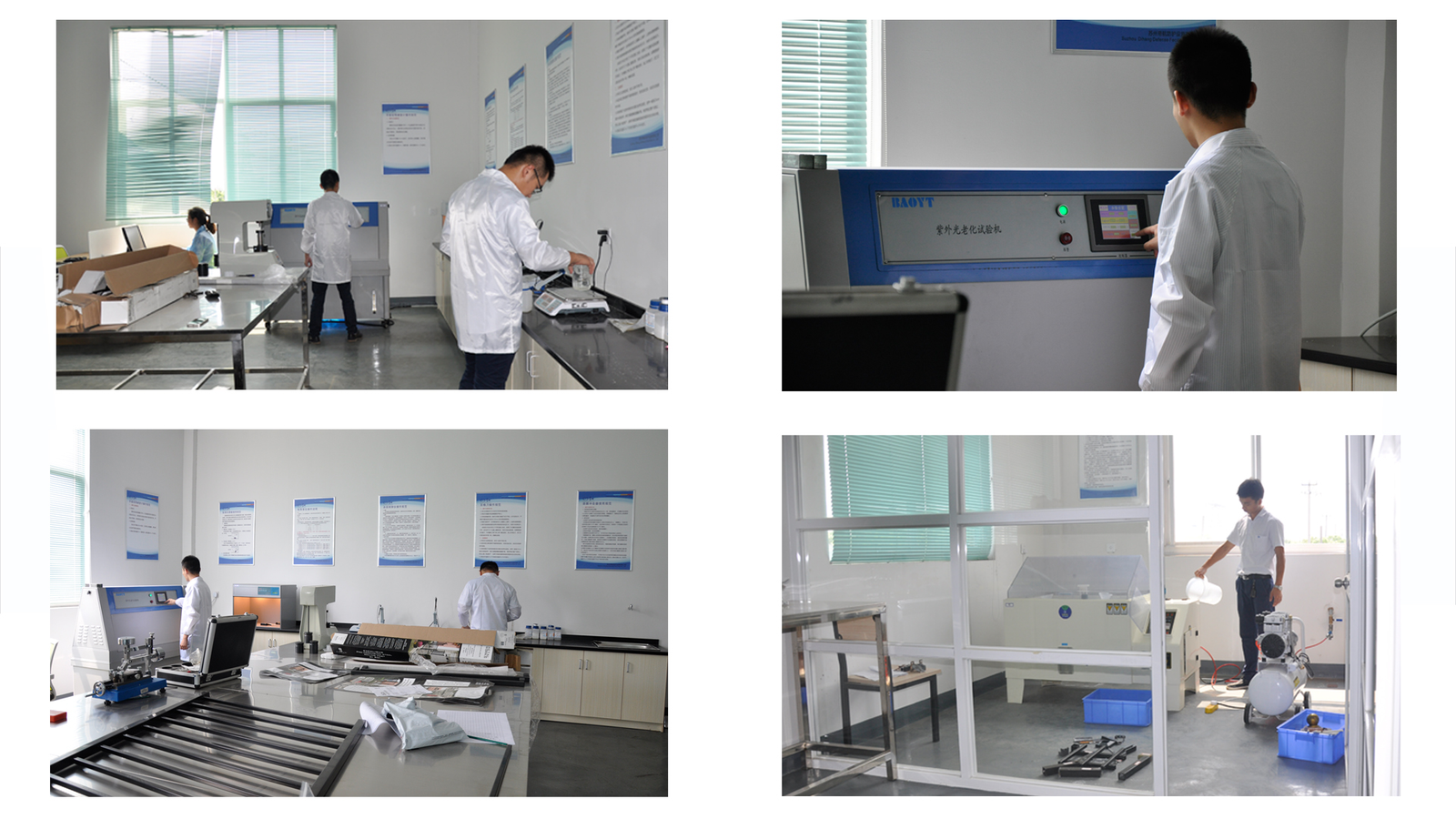

5.Quality Check

Strict quality control before packing : paint glossiness test, aging test, curing temperature test, salt spray test etc.

6.Packaging

Finished products are wrapped with anti-scratch films and loading with steel pallets.

Some are packed in cartons, such as slat section, post kit

Want to see it by yourselves, just feel free to schedule a visit with us.